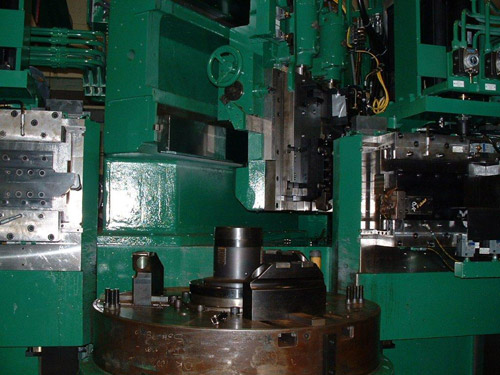

Machine Rebuild of a CNC Vertical Lathe

The CNC vertical lathe highlighted here is used to manufacture 28″ to 42″ railroad wheels from forged steel to tolerances of ±.005″. Replacing a machine of this size and complexity requires a large capital investment, this is why this customer came to us to perform a complete rebuild and retrofit. After a complete assessment of the machine’s condition and the customer requirements, we developed a course of action for the rebuild and retrofit.

The machine was completely disassembled; all components unaffected by the retrofit were rebuilt, and brought back to OEM spec. The retrofit included a complete electrical upgrade, which incorporated replacement of the entire control system, electrical panels, motor drives and starters, as well as a hand pulse generator. A new 150-horse power DC motor was installed as well as new gearboxes and an AC cooling system. The tool layout was entirely re-engineered; we replaced the facing slide, wear groove, force tube actuators, and the expanding and clamping mandrel assemblies, as well as the entire hydraulic and lubricating system. After reassembly and testing, the unit was delivered and installed at the customer’s facility. We performed the complete assembly on site, verifying that it was operational and ready for service.

To learn more about this project, or the processes used to complete it, see the table below or contact us directly.

|

Product Description |

This CNC Vertical Lathe is used to manufacture 28″ to 42″ diameter railroad wheels. |

|

Machine Rebuilding Capabilities |

Primary:

Secondary: |

|

Components |

Facing Slide Assembly

150 hp-DC Motor |

|

Overall Part Dimensions |

28″ to 43″ diameter 12″ high |

|

Tightest Tolerances |

±.005″ |

|

Material Used |

Part is a steel forging railroad wheel |

|

Material Finish |

±.005″ |

|

In process testing/inspection performed |

Test at plant and install at customer’s facilities. |

|

Industry for Use |

Railroad Industry |

|

Volume |

1 |

|

Delivery/Turnaround Time |

3 – 6 months |

|

Product Name |

CNC Vertical Wheel Turning Lathe Rebuild |