Heavy Duty Lathe Build, Repair, Rebuild & Retrofit Services

Leonard Machine Tool Systems provides custom, heavy duty, large capacity lathe build or repair and retrofit services to customers in the component manufacturing industry and specifically the railroad industry.

If your project requires a new machine we build them custom to your specifications and part process. We build both horizontal and vertical heavy duty CNC lathes. For more detailed information please see the link below.

If you are looking to rebuild your current lathe the process can include converting the lathe from mechanical contouring using hydraulic tracers to a CNC controlled system. Each project is unique, but each rebuild generally includes disassembling, assessing, repairing/rebuilding/retrofitting, all systems of the machine to bring it up to current machine tool standards. Systems addressed include the mechanical, hydraulic, electrical and lubrication system.

Customers who have converted to CNC controls have experienced substantial increase in productivity, finish quality, and reduced changeover time. The equipment is most commonly used to machine railroad wheels and railroad axles.

Available for service calls when necessary, we are dedicated and committed to building customer relationships and satisfaction. To learn more about our machinery, please contact us for more information.

Heavy Duty Lathe Build, Repair, Rebuild & Retrofit Capabilities:

|

General Capabilities |

Build |

|

Processes |

Clean |

|

Build / Rebuild |

Large Capacity Turning Lathes, Vertical Turning Lathes, Hollow Mill & Center Drill, Shuttle Bores, Face Mill, Transfer Machine, Fixtures |

|

Conversion |

CNC Controls |

|

Parts / Components |

Housing Slides |

|

On-Site |

Service Calls Available |

Additional Information:

|

Industries Served |

Machine Tool |

|

Intended Applications |

Railroad Wheels |

|

Industry Standards Met |

Mil-Spec |

|

File Formats Accepted |

Smirt Ware |

-

New Custom CNC Vertical Lathe Build

A customer in the railroad industry was in need of a custom designed lathe that could accommodate the turning of components up to 43″ in diameter, 12″ high, and up to 1200 lbs. It also had to satisfy their run rate of 15, 36″ diameter parts per hour, to tolerances of ±005″. The entire system was custom designed from the customer’s concept and part prints, which included complete sets of prints and 2D engineering drawings. The finished machine, which measured 160″ x 170″ x 240″, runs on 460 volts and features a 150 HP motor, running 240 vol...

-

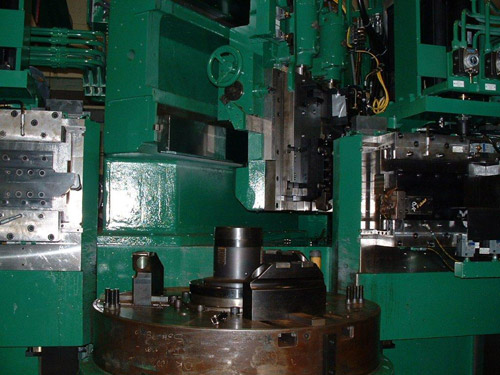

Machine Rebuild of a CNC Vertical Lathe

The CNC vertical lathe highlighted here is used to manufacture 28″ to 42″ railroad wheels from forged steel to tolerances of ±.005″. Replacing a machine of this size and complexity requires a large capital investment, this is why this customer came to us to perform a complete rebuild and retrofit. After a complete assessment of the machine’s condition and the customer requirements, we developed a course of action for the rebuild and retrofit. The machine was completely disassembled; all components unaffected by the retrofit were rebuilt, and brought back to OEM ...